- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

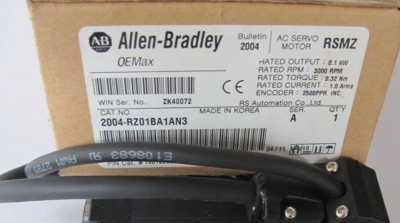

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Động cơ rung, đầm rung Xinxiang Hongda YZS, YZU series vibration motors

Động cơ rung, đầm rung Xinxiang Hongda YZS, YZU series vibration motors

Tình trạng sản phẩm:

The company promises: the production of vibration motor 100% pure copper wire, vacuum impregnating paint, B / F grade insulating resin! This store's vibration motor has passed the national CCC certification, please rest assured to use, quality assurance, where our products sign a formal contract, one year warranty.

1. Structure and application of YZS / YZU / YZD vibration motor:

The YZS / YZU / YZD vibration motor is installed with a set of adjustable eccentric blocks on both sides of the rotor shaft of the motor, and the centrifugal force generated by the rotation of the eccentric blocks is used to transfer the excitation force to the vibration mechanical equipment to make the vibration machinery work. Vibration motor has large excitation force, low energy consumption, low noise, long life, and simple and convenient maintenance. Widely used in silo, hopper, chute wall vibration, it is also an ideal excitation source for various vibration machinery such as vibrating screen, vibrating feeder, vibrating conveyor, vibrating hopper, etc. It is power, metallurgy, mining, coal , Building materials, chemical industry and other necessary equipment, has a wide range of applications.

Second, YZS / YZU / YZD vibration motor installation and use:

YZS / YZU / YZD vibration motor is a three-phase 380V 50HZ asynchronous motor, closed self-cooling, can be installed horizontally and inclinedly. When YZS / YZU / YZD vibration motors work continuously, the surrounding air shall not contain corrosive and explosive gases, and the ambient temperature shall not exceed 40 degrees. When installing the vibration motor on the vibration machine, the foot bolts of the vibration motor must be tightened, and a flat and spring washer must be added under each nut. In the initial operation of the vibration motor, due to the running-in between the bolt, nut and base plane, the tightening will be reduced Due to the force, there is a small looseness, so the foot bolts of the motor should be tightened multiple times at the beginning of the operation, and it should be tightened once a day at the beginning, and checked once a week after two weeks.

YZS / YZU / YZD vibration motors generally run once every 4-6 months for small maintenance and once a year for major maintenance. Remove the machine's volume of dust during minor repairs, check the insulation resistance of the coil and the connection is firm, and remove hidden dangers in time. The motor should be disassembled during overhaul, and the inside and outside should be blown clean with compressed air, check the bearing for wear, and replace with new grease. The YZS / YZU / YZD vibration motor may be damp during transportation or when it is left idle for a long time. Before use, use a 500V megger to check the insulation resistance of the winding. The bearing of the vibration motor should be replenished regularly with grease (2 # industrial lithium base grease), usually every 4-6 months. When the vibration motor is in a non-working state, fill it with an oil gun at the oil nozzle.

3. Technical parameters of YZS / YZU / YZD vibration motor:

YZS / YZU / YZD-5-4 vibration motor

Exciting force: 5KN

Power: 0.25KW

Current: 0.75A

Vibration frequency (speed): 1500 times / minute

Note: The installation size of this motor is 180 mm * 110mm * 4Φ18mm , if you need to change it, please take the initiative.

This motor is generally installed on mechanical equipment such as linear screens, vibrating screens, dewatering screens, in-line screens, hot ore screens, vibrating mills, etc., used in food, chemical, building materials, thermal power, dust removal, environmental protection, mining, metallurgy, pharmaceutical In the industries of cement, fertilizer, casting, ceramics, abrasives, etc.

4. YZS / YZU / YZD vibration motor workshop real shot:

-

- Máy sấy gió nóng hình vuông, square electric heater Rui Fu Te DRF-3KW, DRF-06KW, DRF-09KW, DRF-15KW Liên hệ

-

- Máy sấy gió nóng công suất, electric hot air blower Baogong (BGE) BG-C15/3, BG-C30/3, 15/30KW Liên hệ

-

- Lò xo nén chổi than, YZR carbon brush stainless steel constant pressure spring YZR112/132/160/180/200/250/280 Liên hệ

-

- ĐỘNG CƠ ĐIỆN 3 PHA Y SERIES Liên hệ

-

- CHỔI THAN MORGAN D172 25X32X60MM Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com