- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

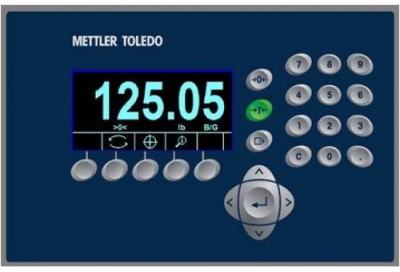

Hiển thị điều khiển cân V8016N weighing display control instrument decrement control peak retention RS485 communication force measuring instrument batching scale

- YB-V8016N standard

- YB-V8016N Peak Hold

- YB-V8016N-A with current transmitter

- YB-V8016N-V with voltage transmitter

- YB-V8016N-MBUS with 485 communication

- YB-V8016N-F reduction control

Tình trạng sản phẩm:

- Model: LJYB-V8016N

- Brand: Lianjie Wanwei

- Material: Polymer

- Type: Black YB-V8016N, standard black YB-V8016N, peak retention black YB-V8016N-A, black YB-V8016N-A with current transmission, black YB-V8016N-V with voltage transmission, black YB-V8016N-MBUS with 485 communication, black YB-V8016N-F Decrease control defaults to 220V, please note that 24V is required

- Output model category: digital sensor

- Applicable scenarios: silos, solenoid valves, automation, data acquisition;

- Sensor category: other

- Colour: Black

- Size: 160x90x80mm

- Working voltage: 220V

| V8016N instrument manual |

- Introduction:

The instrument adopts 24-bit A/D converter and cooperates with various sensors and transmitters to realize the measurement, display, alarm monitoring, and data acquisition of physical parameters such as pressure, flow, level, composition analysis, force and mechanical quantities. and record.

2. Technical parameters:

| working environment | Temperature: 0-50℃ | show | Dual 5-digit high-brightness red LEDs |

| Humidity: 20-90%RH | output excitation voltage | 5V ±5% (powering the sensor), current <50MA | |

| measurement accuracy | ± 0. 2 % FS ± 1 word | voltage | AC195~242V, power consumption< 5w |

| Measurement and control cycle | 0.2 seconds; can be increased to 0.05 seconds |

|

|

3. Key introduction:

" SET " key: setting key " > " key: shift key or tare key (peak meter)

" ∧ " key: up key " CLR " key: peak value reset key or tare key (upper and lower limit instruments)

4. Dimensions:

| Face frame size ( mm ) | Case size (mm) | Hole size (mm) | |||

| Width | high | h | L | WC | HC |

| 160 | 80 | 74 | 90 | 150 | 76 |

5. Description of contents:

| symbol | name | scope |

| SAL | OUT1 relay | 00000~ full scale |

| SPL | OUT1 Deviation | 0 <SPL<SAL |

| SA H | OUT2 relay | 00000~ full scale |

| SPH | OUT2 Deviation | 0 <SP H <SAH |

| SL | Zero calibration value | 00000 |

| SH | Load Calibration | More than half of full scale |

| SD | decimal place | 0~3 |

| ID | Division value | 1.2.5.10.20 |

| CLTF | Tare key selection | 0.1 |

| FIL | weight filtering degree | 1 to 9 |

6. Operating Instructions:

- Press the " SET " key for more than three seconds to display " SAL " to set the OUT1 relay, and then press the " SET " key to display " SPL ", at this time the deviation of OUT1 can be set.

Deviation Explanation When SPL=0 , if the current display value > SAL , then OUT1 pulls in; if the current display value < SAL , then OUT1 releases.

When SPL ≠ 0 , if the current display value > SAL+SPL , then OUT1 is engaged; if the current display value < SAL — SPL , then OUT1 is released.

- Press the " SET " key to display " SA H " to set the OUT2 relay, and then press the " SET " key to display " SPH " to set the deviation of OUT2 , the setting method is the same as above.

- Press the " SET " key to display " CIN ", which means to enter the password, if the password is wrong, it will automatically exit (the password is " 00000 " when leaving the factory). After the password is correct, if you do not want to change the password, press the " SET " key to enter the next step. If you want to change the password, press the " CLR " key to display " CON ", enter 5 digits as a new password, and press the " SET " key to enter the next step .

- Press the " SET " key to display " S L " , no load is applied, and the zero point can be calibrated

- Press the " SET " key to display " SH ", and the load calibration can be performed, add the load (at least half of the full scale), and input the corresponding display value.

- When " Sd " appears after pressing the " SET " key , it means to adjust the setting of the decimal point. Press the up key to change the setting of the decimal point.

- Press the " SET " key to display " Id " to set the division value of the meter;

- Press the " SET " key to display " CLTF " to select the tare key. When " CLTF " is 0 , press the " CLR " key to tare the meter. When it is 1 , press " CLR " to not tare the meter;

- Press the " SET " key to display " FIL " to set the weight filter level, the level can be selected from 1 to 9 , the larger the value, the slower the display, this value affects the stability mark, the larger the value, the slower the stability mark. Press the " SET " key to return to the working state. (Or press the " CLR " key to back up the calibration data for emergency use, for internal use by the manufacturer)

7. Matters needing attention:

- If ' E1 ' appears on the meter, it means that the sensor is not connected or the sensor signal is too large.

8. Emergency treatment (for internal use by the manufacturer)

-

- If the password is forgotten, press and hold the " CLR " key to power on, and the password will be restored to ' 00000 '.

- If the setting is wrong or there is a display but the button does not work, press the " ∧ " button to power on and restore the factory backup.

3 . Press the " > " button to power on ( do not release the button ) , the digital tube changes between 0 and 1, when the display "0" is released, it is the upper and lower limit meter, and "1" is the peak meter.

Product display:

-

![Hiển thị điều khiển cân B60R[F]](/assets/shops/2019_04/o1cn01hq7f1t1qrgemsyotz_1831641973.jpg)

- Hiển thị điều khiển cân B60R[F] Liên hệ

-

![Bộ chuyển đổi tín hiệu cân M60S[L] Weighing Force Control Module Rail Type Peak Detection Peak Hold Automatic Checkweighing](/assets/shops/2019_04/o1cn01hmmdlz1qrgelvyzt9_1831641973.jpg)

- Bộ chuyển đổi tín hiệu cân M60S[L] Weighing Force Control Module Rail Type Peak Detection Peak Hold Automatic Checkweighing Liên hệ

-

- Hiển thị điều khiển cân V4896H weighing display control instrument peak reserved current voltage transmission RS485 communication batching scale Liên hệ

-

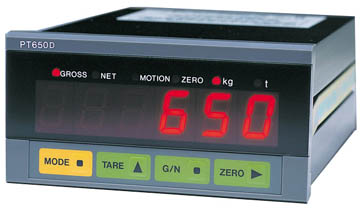

- Bộ điều khiển hiển thị cân Zhimei PT650D precision weighing display controller RS232 instrument mixing station batching scale DC computer Liên hệ

-

- Bộ điều khiển hiển thị cân Zhimei PT350C weighing transmitter amplifier 0-5V 4-20mA mixing tank batching instrument Liên hệ

-

- Bộ điều khiển hiển thị cân Zhimei PT650M-02 precision weighing display control instrument RS232 4-20mA mixing station ingredients Liên hệ

-

- Bộ điều khiển hiển thị cân CHIMEI Zhimei CB900F PT650F four-material two-speed ingredient packaging weighing display control instrument Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, CHIMEI weight transmitter PT350D Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, CHIMEI weight transmitter PT350C Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com