- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Van điện từ, van khí,ZCRB electromagnetic emergency shut-off valve gas emergency shut-off valve DN25 32 40 50 65 80 100

Tình trạng sản phẩm:

First, the gas emergency shut-off valve - an overview

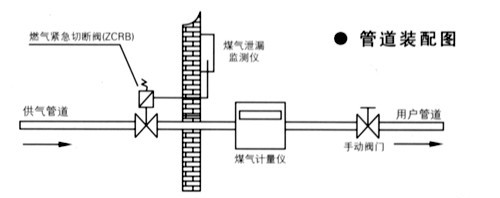

ZCRB series gas emergency shut-off valve is a new type of safety matching device for gas pipeline engineering, mainly used in the following occasions:

1. Connect to the flammable gas leak monitoring instrument. When the instrument detects the leakage of flammable gas, it automatically closes the main gas supply valve, cuts off the supply of gas, and timely stops the occurrence of a vicious accident.

2. Connect to the limit temperature (or pressure) safety controller of the thermal equipment. When the temperature or pressure of the detection point in the equipment exceeds the set limit value, the air supply valve is automatically closed quickly to stop the supply of fuel.

3. Connect to the central fire alarm system of the high-rise building. When a fire occurs in the building, the gas supply in the building is automatically cut off to prevent the gas explosion.

4. Set BZCK gas emergency shut-off valve in the gas supply pipe network of the city or factory, which can be centrally controlled in the central control room, remotely remotely controlled, and emergencyly shut down the pipeline at the accident site.

This series of products has excellent technical performance, low load loss and high reliability. It is suitable for flammable gases such as gas, natural gas and liquefied petroleum gas. It is widely used in gas supply pipe network systems, gas heat plant workshops, gas boiler rooms and residential facilities.

Second, the valve function and working principle

This series of valves is a normally open pulse-trigger type solenoid valve with accident self-locking and manual reset function.

1. The valve is in the normally open state during daily work, and the solenoid valve coil is in a power-off state and does not consume electrical energy.

2. When the accident occurs, the valve coil is energized instantaneously, triggering the valve to close quickly and enter the self-locking state. At this time, even if the power is removed, the valve is still in the self-locking closed state and will not automatically re-open.

3. This valve adopts pilot-operated valve flap, which is easy to open. Even if the pressure reaches 6bar, it is very easy to open. The diameter is larger than DN125. The lever handle is used to make the valve reach the target switch with low effort and speed.

4. When the staff handles the accident and manually restarts the valve, the gas supply will be resumed.

A normally closed emergency shut-off valve with a power-off shut-off is also available upon request.

Third, the gas emergency shut-off valve - technical parameters:

1. Applicable to gas, natural gas and liquefied petroleum gas.

2, valve specifications: threaded connection G1/2 ", G3 / 4", G1 "; flange connection DN25 ~ 350

3, working pressure: 0.5bar ~ 6bar

4, electrical protection level: CEI IP65/IP67

5, explosion-proof grade: Eexm II T4 / Eexm II T5

6, working voltage and electric power: AC AC220V, 50Hz/14V; DC DC12V/8.5W, DC24V/8.5W

7, operating coefficient: uninterrupted output or pulse type

8, electrical connection: plug-in (regardless of positive and negative)

9, coil power: ≤ DN100, AC AC 220V at 20 ° C, 50Hz / 24VA DC DC24V, / 24W coil model: MF-1 (2 ≥ DN100, AC AC220V at 20 ° C, 50Hz / 90VA DC DC24V, / 85W coil model: ZCLF-1(2)

10, working environment temperature: -15 ~ 60 ° C

11, sealing material: NBR rubber

12, valve body material: brass, stainless steel, carbon steel

13, valve closing time: less than 1 second

Fourth, the manual reset operation process

When the valve is cut off and the pipeline leak is removed, the staff needs to manually pull up the manual reset lever when the manual reset is required. When the “click” is heard, the valve is completely opened.At this time, even if you release your hand, it will not be cut off. (unless the valve coil is energized again).

Note: Manual reset must be operated when the solenoid valve coil is de-energized.

Five, gas emergency shut-off valve - performance specifications:

| Pressure Level | Normal temperature test pressure | |||

| case | seal | Low pressure seal | ||

| Nominal pressure (MPa) | 1.6 | 2.4 | 1.76 | 0.6 |

| 2.5 | 3.75 | 2.75 | 0.6 | |

| 4.0 | 6.0 | 4.4 | 0.6 | |

| proper temperature | -15~60°C | |||

| | ||||

Sixth, gas emergency shut-off valve - main parts and materials:

| Part Name | material | |

| "-1 thread" | DN25-DN350 (flange) | |

| Valve body | brass | Carbon steel (stainless steel) |

| Self-locking body | Brass (aluminum alloy) | |

| Valve stem | stainless steel | stainless steel |

| Sealed river | NBR rubber | |

Seven, gas emergency shut-off valve - specifications and installation size table

| Specification (DN) | L | H | D | D1 | D2 | Z-¤d | Remarks |

| | | | | | | | |

| | | | | | | | |

| | | | | | | | |

| 25 | 160 | 180 | 115 | 85 | 65 | 4-¤14 | Flange connection |

| 32 | 180 | 200 | 135 | 100 | 78 | 4-¤18 | |

| 40 | 200 | 200 | 145 | 110 | 85 | 4-¤18 | |

| 50 | 230 | 220 | 160 | 125 | 100 | 4-¤18 | |

| 65 | 290 | 255 | 180 | 145 | 120 | 4-¤18 | |

| 80 | 310 | 320 | 195 | 160 | 135 | 8-¤18 | |

| 100 | 350 | 380 | 215 | 180 | 155 | 8-¤18 | |

| 125 | 400 | 405 | 245 | 210 | 185 | 8-¤23 | |

| 150 | 480 | 458 | 280 | 240 | 210 | 8-¤23 | |

| 200 | 600 | 530 | 335 | 295 | 265 | 8-¤23 | |

| 250 | 650 | 600 | 390 | 350 | 320 | 12-¤23 | |

| 300 | 750 | 650 | 440 | 400 | 368 | 12-¤23 | |

| 350 | 850 | 750 | 500 | 460 | 428 | 12-¤23 |

-

- Van thủy lực HIDEKE SWH-G02-C2-10 SWH-G02-C3-10 SWH-G02-C4-10 SWH-G02-C5-10 SWH-G02-C6-10 SWH-G02-C7-10 SWH-G02-C9-10 SWH-G02-D2-10 SWH-G02-C2-20 SWH-G02-C3-20 SWH-G02-C4-20 SWH-G02-C5-20 SWH-G02-C6-20 SWH-G02-C7-20 SWH-G02-C9-20 SWH-G02-D2-20 Liên hệ

-

- Van thủy lực Risuny D5-03-2B2-A25 D5-03-2B2-D2 D5-03-2B2L-A25 D5-03-2B2L-D2 D5-03-2B2B-A25 D5-03-2B2B-D2 D5-03-2B3B-A25 D5-03-2B3B-L-A25 D5-03-2B3B-D2 D5-03-2B3-A25 D5-03-2B3-D2 D5-03-2B2A-A25 D5-03-2B2A-D2 D5-03-2B3A-A25 D5-03-2B3A-D2 D5-03-2B8-A25 D5-03 Liên hệ

-

- Van thủy lực Risuny D5-02-3C2-D2 D5-02-3C2-A25-R D5-02-3C60-D2 D5-02-3C60-A25-R D5-02-3C3-D2 D5-02-3C3-A25-R D5-02-3C4-D2 D5-02-3C4-A25-R D5-02-3C5-D2 D5-02-3C5-A-25-R D5-02-2D2-D2 D5-02-2D2-A25-R D5-02-3C10-D2 D5-02-3C10-A25-R D5-02-3C9-D2 D5-02-3C9-A25- Liên hệ

-

- Công tắc áp lực Shida pressure relay HED80A1X/50L24KW HED80A1X/100L24KW HED80A1X/200L24KW HED80A1X/350L24KW HED80A1X/50L220KW HED80A1X/100L220KW HED80A1X/200L220KW HED80A1X/350L220KW HED80A1X/ Liên hệ

-

- Van thủy lực Shida DBEM10-71/50YG24K4M DBEM10-71/100YG24K4M DBEM10-71/200YG24K4M DBEM10-71/315YG24K4M DBEM10-70/50YG24K4M DBEM10-70/100YG24K4M DBEM10-70/200YG24K4M DBEM10-70/315YG24K4M DBEM10-7X Liên hệ

-

- Van thủy lực Shida 4WREE10E3-50-22/G24K31/A1V 4WREE10E50-22/G24K31/A1V-655 4WREE10E50-2X/G24K31/A1V 4WREE10E75-20/G24K31/A1V 4WREE10E1-75-2X/G24K31/A1V 4WREE10W75-22/G24K31 Liên hệ

-

- Van thủy lực Shida 4WRAE10E60-22/G24K31/F1V 4WRAE10E60-2X/G24N9K31/A1M 4WRAE10E30-2X/G24K31/F1V 4WRAE10E30-2X/G24N9K31/A1M 4WRAE10E1-60-2X/G24K31/F1V 4WRAE10E1-60-2X/G24N9K31 Liên hệ

-

- Van thủy lực Shida DVP6-1-10/ DVP8-1-10/ DVP10-1-10/ DVP12-1-10/ DVP16-1-10/ DVP20-1-10/ DV6-1-10/2 DV8-1-10/2 DV10-1-10/2 DV12-1-10/2 DV16-1-10/2 DV20-1-10/2 Liên hệ

-

- Van thủy lực Shida Z2FS6-30 Z2FS6-30/S Z2FS6-30/S2 Z2FS6-2-40/2QV Z2FS6-2-40/2Q Z2FS6-2-40/1QV Z2FS6-2-40/1Q Z2FS6-2-4X Z2FS6-2-4X/S2 Z2FS6-5-40/2QV Z2FS6-5-40/2Q Z2FS10-20 Z2FS10-20/S Liên hệ

-

- Van thủy lực Shida ZDR6DP2-40/25YM ZDR6DP2-40/75YM ZDR6DP2-40/150YM ZDR6DP2-40/210YM ZDR6DA2-40/25YM ZDR6DA2-40/75YM ZDR6DA2-40/150YM ZDR6DA2-40/210YM ZDR6DB2-40/25YM ZDR6DB2-40/75YM Liên hệ

-

- Van thủy lực Shida DAW10B-1-30B/80G24NZ5L DAW10B-1-30B/160G24NZ5L DAW10B-1-30B/315G24NZ5L DAW10B-1-30B/80W220-50NZ5L DAW10B-1-30B/160W220-50NZ5L DAW10B-1-30B/315W220-50NZ5L DAW10B-2-30B/80G24NZ5L DAW10B-2-3 Liên hệ

-

- Van thủy lực Shida DB10-2-5X/50 DB10-2-5X/100 DB10-2-5X/200 DB10-2-5X/315 DB10-2-5X/350 DB10-2-52/50 DB10-2-52/100 DB10-2-52/200 DB10-2-52/315 DB10-2-52/350 DB20-2-5X/50 DB20-2-5 Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com