- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

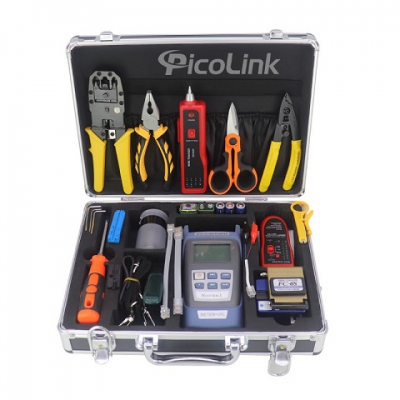

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Máy nghe tiếng ồn vòng bi, máy nghe độ ồn cơ học, máy đo độ ồn động cơ HLS-10, APM-20

Máy nghe tiếng ồn vòng bi, máy nghe độ ồn cơ học, Mechanical fault stethoscope, vibration meter motor bearing, abnormal sound detector HLS-10, APM-20

Tình trạng sản phẩm:

HLS-10 / APM-20 / RDS-10 Mechanical Failure Stethoscope Product Description:

HLS-10 / APM-20 / RDS-10 mechanical failure stethoscope can detect the internal vibration of the machine. With a highly sensitive hand-held sensor, the weak signal is picked up and amplified to distinguish between normal and abnormal signal locations. Strong versatility, suitable for fault diagnosis of any internal parts of machinery. HLS-10 mechanical failure stethoscope uses IC circuits and transistors to assemble. It has a small size and light weight, and is easy to operate. It is a necessary tool for equipment maintenance personnel. It is widely used in ships, automobiles, chemical, metallurgical, machine tools, household appliances, machinery, and other industries.

Its main uses are:

1) It can quickly detect mechanical noise from diesel engines, cylinders, and automobiles, and accurately locate the fault.

2) It can identify abnormal noise and noise from various engines and motors, so as to avoid accidents.

3) The operation status of the automatic assembly line of various industrial and mining enterprises can be monitored to ensure the normal production of the assembly line.

4) It is applicable to various chemical industries to detect and monitor the flow status and blockage in various pipelines.

5) Can monitor abnormal noise in each boiler and abnormal noise in each reaction pot.

6) It is also possible to quickly judge the running status of various bearings.

7) It is applicable to the monitoring of ship operation status in the shipping and shipbuilding industries.

8) It is also applicable to the maintenance of various vehicles by the army.

9) Can also be used as a maintenance tool for household appliances.

HLS-10 / APM-20 / RDS-10 mechanical failure stethoscope technical parameters:

1 ) Frequency response: 100Hz ~ 10kHz.

2) Input impedance:> 15MΩ.

3) Allowable ambient noise: 100dB.

4) Ambient temperature: -10 ℃ ~ + 55 ℃.

5) Power supply: 9V battery.

6) Mass: 300g.

7) Dimensions: 205mm × 50mm × 40mm

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com