- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

công tắc báo mức float switch Tianen TEK-1 cable float switch, float level controller

Tình trạng sản phẩm:

【Name】: Tianen instrument TEK-1 float control switch

[Specifications]: TEK-1 2 meters 3 meters 4 meters 5 meters 10 meters (including the total length of the float)

Rated current and voltage: 10 (8A) 250V ~ 10 (4A) 380V

(For safety reasons, it is recommended to use the working voltage DC24V)

Working temperature: -10 ℃ ~ 60 ℃ ( plastic )

Control range: ≥0.2m

Working life: ≥50000

【Heavy hammer installation method】

1. After passingthe cable ofthe TEK float switch from the round hole in the center of the weight, please pay attention to separate the four holes with holes in the weight

A small card closely, gently push the weight you want in a fixed position,

2 ,the weight on the plastic ring as long as the tapped i.e. not slip, in use, preferably a copper wire or other thing and then, the weight

The hammer is fixed on the cable (the upper and lower ends are stuck) or on the inner wall of the container to prevent the heavy hammer from sliding and affecting the control of the water level.

Please pull the cable directly to the control box, try to avoid using the middle connector; if there is a connector, it is absolutely not allowed

Immerse the cable connector in liquid!

【Performance characteristics 】

1. The "TEK-1" float control switch is a switch that can adjust the liquid level in the barrel-tank or well. It can be adjusted automatically-easy

Operation-easy to install-safe and reliable-maintenance-free-non-toxic recycling renewable environmentally friendly float switch for water control and drainage

control. It has resistance to sewage, and is widely used in household-factory and mine pools-oil-acid and alkali pools-barrels-tanks-tanks, etc.

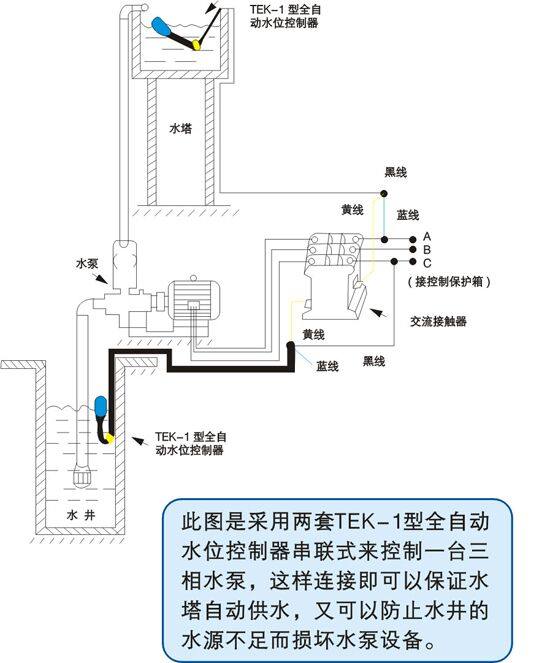

In the device. If two controllers are connected. One is placed in the water tower and the other is placed in the well to control the pump, which can prevent the water source from

Open the pump enough to damage the pump equipment; three controllers can also be connected in series, one to the water tower, the other to the filter tank and one

It can be controlled at the same time when it is put into river water (well), which can prevent the pump equipment from being damaged due to insufficient water source to open the pump;

The controllers are connected in series, and one is put into the river water (well) to control two pump equipments simultaneously.

| 2. Installation and wiring methods: | |||||||

|

-

- Bộ điều khiển nhiệt độ JCD-33A-A/M JCD-33A-A/M BK JCD-33A-R/M BK A2 C5 JCD-33A-R/M BK C5 JCD-33A-S/M JCD-33A-S/M BK C5 JCD-33A-S/M A2 JCD-33A-S/M BK DS Liên hệ

-

- Van tỷ lệ Parker proportional valve D41FCB31FC1NE70 D41FCE01FC1NE70 D41FBE01FC1NF00 D41FBE01FC4NF00 Liên hệ

-

- Van kiểm tra Camozzi check valve VNR-210-1/8 VNR-205-M5 VNR-843-07 VNR-238-3/8 VNR-212-1/2 VNR-234-3/4 VNR-201-1 Liên hệ

-

- Đồng hồ Shihlin WT409-10100002AS WT409-20100002AS WT409-30100002AS WTH49-10100002AS WTH49-20100002AS WTH49-30100002AS Liên hệ

-

- Bộ điều khiển tốc độ quạt ALCO Emerson fan speed regulator pressure sensor FSO-N15 FSY-42S FSY-43S FSO-N30 Liên hệ

-

- Công tắc áp suất pressure switch SG307-F-150 ST307-350-B SG307-F-350 SG307-F-55 ST307-150-B SG307-F-V2-150 ST307-SCH-V2-350-B ST307-V2-350-B SG307- F-V2-55 SG307-F-150-B Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com