- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

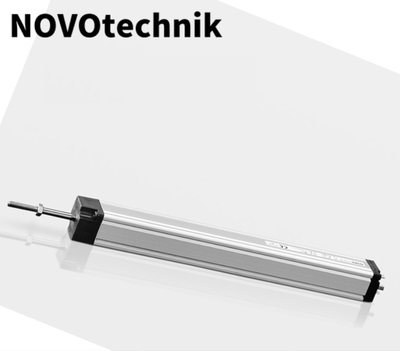

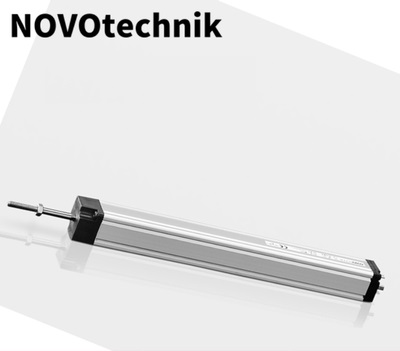

Cảm biến dịch chuyển, novotechnik linear displacement sensor LWH-0050,LWH-0075,LWH-0100,LWH-0130,LWH-0150,LWH-0175,LWH-0200, LWH-0225, LWH-0250, LWH-0275, LWH-0300, LWH-0325, LWH-0360, LWH-0450, LWH-0500, LWH-0550, LWH-0600, LWH-0650, LWH-0750, LWH-0900

Tình trạng sản phẩm:

Cảm biến dịch chuyển, novotechnik linear displacement sensor LWH-0050,LWH-0075,LWH-0100,LWH-0130,LWH-0150,LWH-0175,LWH-0200, LWH-0225, LWH-0250, LWH-0275, LWH-0300, LWH-0325, LWH-0360, LWH-0450, LWH-0500, LWH-0550, LWH-0600, LWH-0650, LWH-0750, LWH-0900

NOVOTECHNIK electronic rule available from stock : LWH 75 / LWH 100 / LWH 130 / LWH 150 / LWH 175 / LWH 200 / LWH 225 / LWH 250 / LWH 275 / LWH 300 / LWH 325 / LWH 375 / LWH 400 / LWH 450 / LWH 500 / LWH 550 / LWH 600 / LWH 750 / LWH 900

This product is widely used in injection molding machines, die casting machines, rotary cutting machines, planing machines, woodworking machinery, printing machines, spray coating, machine tools, robots, automation equipment, engineering monitoring computer-controlled sports equipment and other occasions that require accurate measurement of displacement.

LWH series sensors

Linear displacement sensor, working range up to 900mm

Protection class IP 55

Features:

• Under different application conditions, the service life is up to 100 x 106 times

• Excellent linearity, up to ± 0.04%

• Resolution higher than 0.01mm

• High operating speed

• DIN 43 650 standard plug and socket

• Protection class IP 55

This series of sensors is used in measurement and control systems for direct and absolute measurement of displacement and length. The working range is up to 900mm and the high resolution (0.01mm) can provide accurate linear displacement measurement. The structural design of the sensor is considered to be convenient for installation and disassembly.

The internal and external structural surfaces of the sensor have been specially treated to work under high-speed and low-wear conditions. The flexible buffer bearing at the front of the sensor can overcome some minor lateral stress of the transmission rod to ensure the normal operation of the sensor. Processes such as sensor conductive material fixing and structural design ensure that the sensor can work reliably even under the harshest conditions. There are mounting grooves on all four sides of the sensor, so that it is convenient to install the conductive material face down as much as possible during installation, to avoid the presence of tiny debris particles inside the sensor and affect the life of the sensor.

-

- Cầu chì cắt nhanh HAIRO RS96B 500V100A RS96B 500V200A RS96B 500V300A RS96B 500V350A RS96B 500V400A RS96B 500V500A Liên hệ

-

- Cầu chì cắt nhanh HAIRO 107RSM 1000V800A-5a 107RSM 1000V1000A-5a 107RSM 1000V1200A-5a 107RSM 1000V1500A-5a Liên hệ

-

- Cầu chì cắt nhanh HAIRO RSG-3ZK 1000V500A RSG-3ZK 1000V630A RSG-3ZK 1000V800A RSG-3ZK 1000V1000A RSG-3ZK 1000V1200A Liên hệ

-

- Cầu chì cắt nhanh HAIRO RS4 500V600A L104NK RS4 500V800A L104NK RS4 500V1000A L104NK RS4 500V1200A L104NK Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com