- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

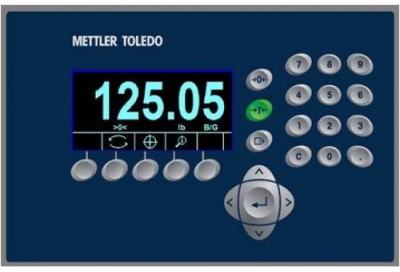

Bộ điều khiển hiển thị cân, Weighing Control Display JY500B3 JY500B1

The heavy control instrument is a dynamic belt scale and batching control instrument based on microcomputer. Using human-machine dialogue on the VFD screen, the weighing flow is directly displayed in Chinese form, and the relevant information is accumulated. Operation and calibration are especially convenient.The instrument has automatic zero calibration, automatic interval calibration, fault alarm automatic diagnosis, optical isolation input / output, standard serial port, built-in PID control output.

- THƯƠNG HIỆU

Tình trạng sản phẩm:

2, environmental parameters

1. Storage temperature - 40 ° C - +70 ° C;

Operating temperature -10 ° C - +50 ° C;

2. Maximum relative humidity: 95%

3, the power supply

220VAC+10%~—15% 50Hz

Fuse 0.5A

EMI/RFI filter

4, weighing sensor

The instrument provides 10VDC, 200mA excitation power supply, and can be connected in parallel with 4 load cells.

Sensitivity, 0.5mV/V-3.5mV/V

Maximum input signal 33mV

Load cell shield grounding

Use the excitation compensation circuit jumper to select local or remote compensation when the cable distance is greater than 60 meters (not more than 900 meters)

5, the motherboard digital input port

The instrument main board provides three programmable input ports to receive dry contact switch signals.

6, the motherboard digital output port

The instrument main board provides 3 programmable output ports and 24VDC open collector output, which can directly drive the control relay.

7, communication board

The instrument can be equipped with a communication board. It can use standard RS-232, RS-485 serial interface and host computer communication board to collect instrument data and operate the instrument, and has two-way communication function.

8, the main performance

Four lines display, select through menu

5 status indicators

Current output of material flow or load

Pulse output of total material weight

Automatic zero adjustment

Automatic zero tracking

Photoelectrically coupled digital inputs and outputs

Alarm and fault prompts

Communication function: RS232, RS485 multi-station communication network

One way process control mode: PID control output

9, the main function

All functional software is solidified in the memory chip. When the user installs an optional expansion board or the operator selects through the keyboard, the controller will automatically open the corresponding function.

(1) Measurement function

a, instantaneous flow calculation

The load cell output unit weight signal is multiplied by the speed sensor output unit belt speed signal. This result is instantaneous flow.

b, weight accumulation

The cumulative amount is the total weight of the unit length and the running length, and then converted into engineering units.

C, automatic zero adjustment and automatic adjustment interval

By defining the number of belt turns and belt length is the basis for automatic zero adjustment and automatic adjustment interval.

To accurately calculate the length of the belt, the controller calculates the number of pulses from the speed sensor. When the required number of pulses is accumulated, the controller ends the calibration test, compares the theoretical value with the actual value, and calculates the calibration constant.

d. Automatic zero tracking

When the belt is running, the flow rate is lower than the predetermined value, and the controller performs automatic zero adjustment according to the following steps.

-- Wait for half of the test cycle (“Z” will be displayed)

- Complete a zero test

- Complete automatic zeroing of a test cycle

- As long as the flow value is lower than the automatic zero tracking tracking value, the meter will repeat the above steps

e, one input, two current output signals

Optional input/output expansion board for one voltage/current input and two current output signals

(2) Monitoring function

Status prompt

Process alarm

Setting error

Equipment failure

High flow, low flow, high load, low load alarm

(3) Automatic control of feeding function

The weighing controller provides an independent control current loop. The control current loop is usually used to control the feed amount. The control method is

—— PID=proportional + integral + differential

The controllable process variable is the feed amount, and the flow setting can be set via keyboard input or external analog signal. The control output is a 4-20 mA current loop.

-

![Hiển thị điều khiển cân B60R[F]](/assets/shops/2019_04/o1cn01hq7f1t1qrgemsyotz_1831641973.jpg)

- Hiển thị điều khiển cân B60R[F] Liên hệ

-

![Bộ chuyển đổi tín hiệu cân M60S[L] Weighing Force Control Module Rail Type Peak Detection Peak Hold Automatic Checkweighing](/assets/shops/2019_04/o1cn01hmmdlz1qrgelvyzt9_1831641973.jpg)

- Bộ chuyển đổi tín hiệu cân M60S[L] Weighing Force Control Module Rail Type Peak Detection Peak Hold Automatic Checkweighing Liên hệ

-

- Hiển thị điều khiển cân V8016N weighing display control instrument decrement control peak retention RS485 communication force measuring instrument batching scale Liên hệ

-

- Hiển thị điều khiển cân V4896H weighing display control instrument peak reserved current voltage transmission RS485 communication batching scale Liên hệ

-

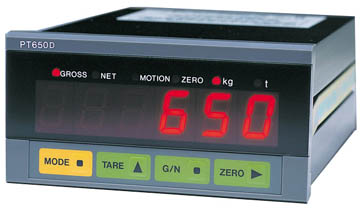

- Bộ điều khiển hiển thị cân Zhimei PT650D precision weighing display controller RS232 instrument mixing station batching scale DC computer Liên hệ

-

- Bộ điều khiển hiển thị cân Zhimei PT350C weighing transmitter amplifier 0-5V 4-20mA mixing tank batching instrument Liên hệ

-

- Bộ điều khiển hiển thị cân Zhimei PT650M-02 precision weighing display control instrument RS232 4-20mA mixing station ingredients Liên hệ

-

- Bộ điều khiển hiển thị cân CHIMEI Zhimei CB900F PT650F four-material two-speed ingredient packaging weighing display control instrument Liên hệ

-

- Bộ chuyển đổi tín hiệu cảm biến tải, chuyển đổi tín hiệu cân, CHIMEI weight transmitter PT350D Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com