- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Công tắc giật dây, công tắc giật dây dừng băng tải, Two-way rope switch , HFKLT2-I,HFKLT2-II

Tình trạng sản phẩm:

1, using environmental conditions

a Ambient temperature -30~+50oC

b Relative temperature is not more than 85

2, the main parameters are shown in the table below

| parameter model | Angle of action | Limit angle | Operating force (kg) | Number of contacts | Contact rating | Reset mode | reliability | Weight (KG) | |

| Normally open | Normally closed | ||||||||

| KLT2-I type | 30o | 60o | 10 | 1 | 1 | AC380V | automatic | >10 sixth power | 3 |

| KLT2-II type | 30o | 60o | 10 | 1 | 1 | Manual | 3.5 | ||

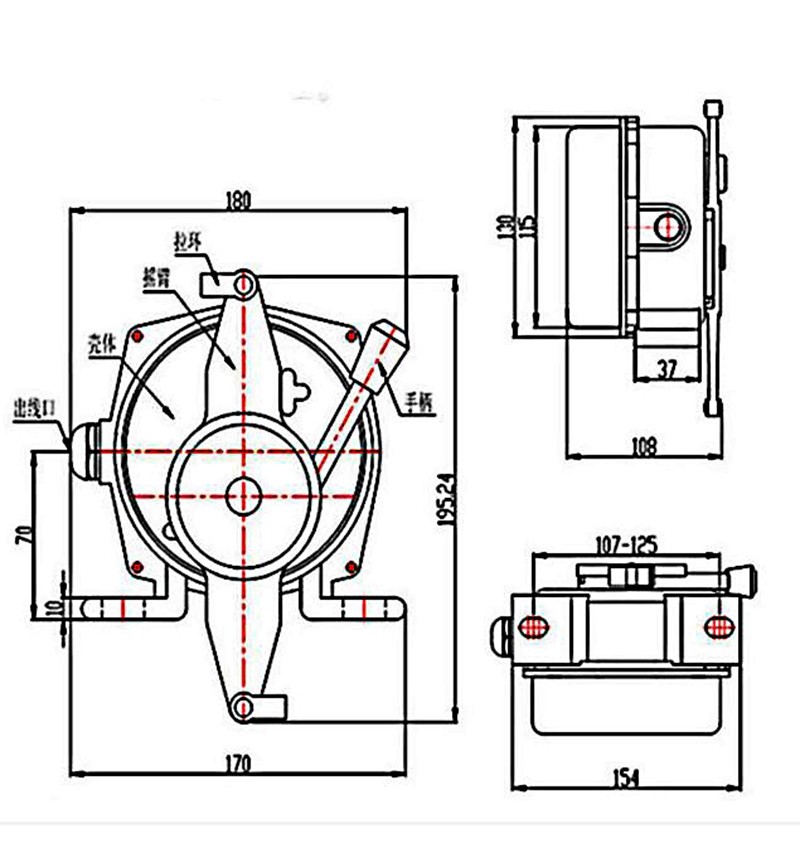

1. This machine adopts aluminum alloy precision die-casting shell, high strength and light weight;

2, the enclosure has a large IP65 protection level and can work in harsh environments;

3, the machine uses the inlet to form the switch, the contact capacity is large, the action is sensitive, reliable, and the structure is shown in Figure 1.

Five, working principle

When an emergency occurs on the belt conveyor, the wire rope attached to the swing arm can be pulled, the swing arm rotates, and the inner cam is driven to close the drive stroke switch, and a stop signal occurs.

After the fault is removed, the limit lever can be pushed to reset.

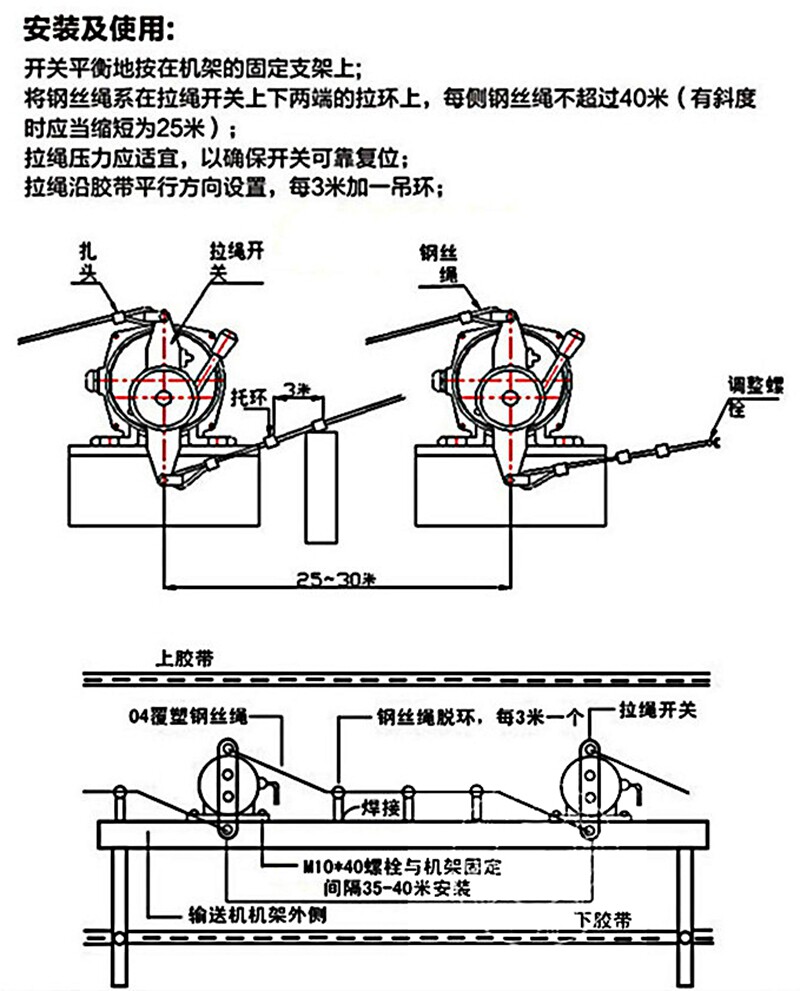

Six, installation adjustment

This machine is generally installed on the racks on both sides of the belt conveyor;

1. Fix the rope switch to the bracket and then solder it to the frame;

2, the distance between the two machines is 25-30m, and the wire rope with the diameter of φ4 is connected, and the tightness should be moderate;

3, in order to influence the self-weight of the small wire rope on the start of the switch, weld a bracket on the frame every 3m, a support wire rope;

4, the user can make the installation bracket, or order it from our factory.

Seven, wiring method

The machine is equipped with a 3-core rubber cable at the factory, and the cable is equipped with a wire number. Refer to Figure 3 for wiring.

Eight, the user must know

Users can order the support ring, adjusting bolt or purchasing wire rope made by our factory.

Nine: in line with national implementation standards: GB12476.1-1990

The two-way rope switch is widely used in steel, cement, power plants, mines and other factories with belt conveyors. This product is installed on both sides of the belt conveyor. It is a protection switch for emergency shutdown of the belt conveyor. Pull the wire rope at any point within the operating distance, cut off the running circuit to stop the whole line, and realize the protection of the belt conveyor and personal safety. When an emergency occurs at the tape transportation site, pulling the steel wire rope attached to the lifting lug is the role of the slider and switch in the machine to send a stop signal.

This product has self-locking protection. It can be reset by pressing the limit lever after the accident is eliminated. It has a long service life. It has good sealing performance and has the advantages of dustproof, shockproof and anticorrosive.

1. Ambient temperature: -30 ℃ ~ + 75 ℃

2. Humidity: not more than 85%

3. Action angle: 30 °

4. Extreme angle: 60 °

5. Action force: ≥10Kg

6, the number of contacts: one opening and one closing can be increased according to customer needs two opening and two closing

7. Contact capacity: AC380V / 5A

8. Reset method: manual reset, automatic reset, manual reset

9. Weight: 1.5Kg

HRLS-I

HRLS-II

HRLS-S

NST2-II

PMI

PMII

KLT2-1

KLT2-2

HFKLT1

HFKLT2

HFKLT1-1

HFKLT1-11

HFKLT1-I

HFKLT1-II

HFKLT2-I

HFKLT2-II

HFKLT2-1

HFKLT2-11

ELS-II

KLT2

HFKLT2

LS-I

LS-II

LLP6-1

LLP6-2

LSF-1

LSF-2

XLLS-I

-

- Công tắc báo lệch băng tải two-stage deviation switch ROS-2DS conveyor belt deviation prevention device ROS-2-FM ROS-2D Liên hệ

-

- Công tắc kéo dây, Pull switch LS-LX-S limit switch ZS7110SVD pull control switch travel switch pull rope switch Liên hệ

-

- Công tắc kéo dây, Pull switch LS-LX-Z limit switch ZS7110VDZ pull rope switch pull control switch limit switch Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải, Pull switch SPS-2D-FM two-way rope switch Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải 2 hướng, bidirectional balance rope switch HFKLT2-P-I, HFKLT2-P-II Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải, Two-way rope switch , HFKLT2-I XLLS-I HFKLT2-2 HFKLT2-II cable hand-in-one Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com