- Bộ lập trình PLC, cáp lập trình

- Màn hình HMI

- Cảm biến, phụ kiện

- Biến tần, khởi động mềm

- Máy cắt, Aptomat, khởi động từ

- Thiết bị đo lường, bảo vệ

- Thiết bị công nghiệp, tự động hóa

- Thủy lực, khí nén, van công nghiệp

- Motor, Servo motor, Servo Amplifier

- Thyristor, Module, SCR, SSR, Diode

- Phụ kiện tủ điện và vỏ tủ điện

- Cáp điện, ống bảo vệ cáp

- Thiết bị điện trung thế, truyền tải

- Thiết bị chống sét, kim thu sét

- Dụng cụ cầm tay, dụng cụ tool

- ATS, UPS, tụ bù, cuộn kháng

-

Thiết bị ngành xi măng, thép, nhiệt điện

-

Thiết bị vật tư điện nhẹ-viễn thông

Công tắc giật dây, công tắc giật dây dừng băng tải 2 hướng, bidirectional balance rope switch HFKLT2-P-I, HFKLT2-P-II

- I. Overview

This machine is used for emergency stop when an accident occurs in the belt conveyor.

Second, the working principle

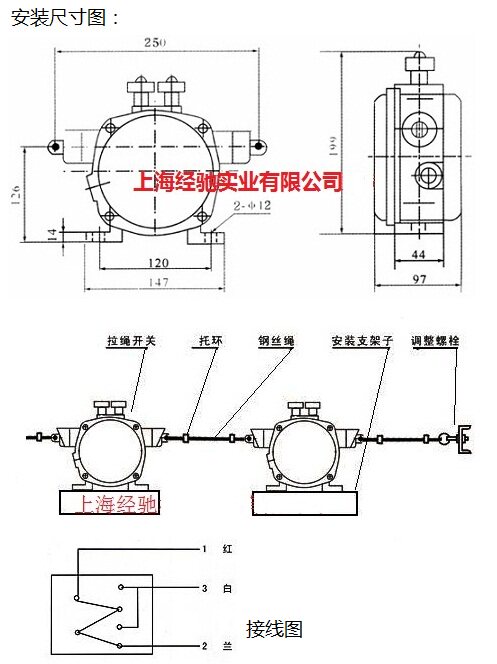

The switch is two-way touch type, one end is fixed on the pull rope bolt, the other end is fixed on the switch arm, the switch is fixed to a fixed point distance of no more than 25 meters, and the distance between the switches is not more than 30 meters. When the external force causes the switch arm to rotate to the alarm (stop At the position, the micro switch operates.

Tình trạng sản phẩm:

Structural features

● The switch is a closed, anti-corrosion cast aluminum enclosure with an IP65 protection rating . It can be used for a long time in harsh working environments.

● Universal installation design makes the cable switch can be installed on the top of the side member of the conveyor or on both sides.

● Integral cover plate, so as to adjust and maintain the switch without removing the wire rod.

● Imported components are used in the machine, with large contact capacity, sensitive and reliable movement.

Fourth, technical parameters

| Environmental conditions | Ambient temperature: -30 ℃ — + 75 ℃ Relative temperature: no more than 85% |

| Action angle | 30 ° |

| Extreme angle | 60 ° |

| Action force (kg) | 10 |

| Contact rating | Two normally open, two normally closed |

| Contact rating | AC380V 5A |

| Reset mode | Type I automatic reset, type II manual reset |

| reliability | > 10 times |

| Weight (kg) | 2.5 |

Five, scope of application

⊙Conventional belt conveyor

⊙Shuttle conveyor

⊙Skirt feed conveyor

Bucket elevator

⊙Packing production line

⊙Stacking / reclaiming system, crane, excavator

Bow ship loading and unloading system

⊙Horizontal feeder

Use and installation

● The switch is installed on the fixed bracket of the rack in a balanced manner;

● Tie the steel wire rope to the pull rings at both ends, each measuring rope should not exceed 30M (it should be shortened when there is a steep slope)

● The pull rope pressure should be appropriate to ensure the reliable reset of the switch;

● The pull rope is set in the parallel direction of the tape, and a lifting ring is added every 10M; the wire rope can be purchased by the factory according to the specifications required by the user.

HRLS-I

HRLS-II

HRLS-S

NST2-II

PMI

PMII

KLT2-1

KLT2-2

HFKLT1

HFKLT2

HFKLT1-1

HFKLT1-11

HFKLT1-I

HFKLT1-II

HFKLT2-I

HFKLT2-II

HFKLT2-1

HFKLT2-11

ELS-II

KLT2

HFKLT2

LS-I

LS-II

LLP6-1

LLP6-2

LSF-1

LSF-2

XLLS-I

-

- Công tắc báo lệch băng tải two-stage deviation switch ROS-2DS conveyor belt deviation prevention device ROS-2-FM ROS-2D Liên hệ

-

- Công tắc kéo dây, Pull switch LS-LX-S limit switch ZS7110SVD pull control switch travel switch pull rope switch Liên hệ

-

- Công tắc kéo dây, Pull switch LS-LX-Z limit switch ZS7110VDZ pull rope switch pull control switch limit switch Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải, Pull switch SPS-2D-FM two-way rope switch Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải, Two-way rope switch , HFKLT2-I XLLS-I HFKLT2-2 HFKLT2-II cable hand-in-one Liên hệ

-

- Công tắc giật dây, công tắc giật dây dừng băng tải, Two-way rope switch , HFKLT2-I,HFKLT2-II Liên hệ

TÂN THÀNH CAM KẾT

- Sản phẩm, hàng hóa chính hãng.

- Giá cả cạnh tranh.

- Dịch vụ chăm sóc khách hàng tận tâm.

Thông Tin Công Ty

Chính sách và quy định

Hỗ trợ khách hàng

THÔNG TIN LIÊN HỆ:

-------------------------------

CÔNG TY TNHH THIẾT BỊ CÔNG NGHIỆP TTH

Trụ sở: số 124 ngõ 79 Yên Hoà-Cầu giấy-HN

Kinh doanh 1 : 0816.861.515

Kinh doanh 2 : 0836.861.515

Email: tthkinhdoanh@gmail.com

Email: tthkinhdoanh01@gmail.com